Alfred University set to launch Space Materials Institute

Alfred University is excited to announce the launch of its new Space Materials Institute (SMI), which has been established in the Inamori School of Engineering to advance the science and technology of materials in support of aerospace and outer space exploration.

The Alfred University Space Materials Institute will be officially launched during a luncheon in the Knight Club, Powell Campus Center, on Thursday, Nov. 7, immediately following the prestigious John F. McMahon Memorial Lecture. The lecture, given by Dr. Kang N. Lee, senior research scientist at the National Aeronautics and Space Administration (NASA) Glenn Research Center, will be presented at 11:20 a.m. in Holmes Auditorium, Harder Hall.

SMI’s model is to facilitate industry and agency projects with Alfred University that engage students in hands-on experiential learning opportunities, while allowing companies to develop and protect intellectual property. Alfred University’s New York State College of Ceramics is a key provider of quality ceramic, glass and materials engineers to the advanced materials workforce pipeline. The Space Materials Institute is working with Alfred University’s Center for Advanced Ceramic Technology (CACT) to initiate and grow New York State capabilities in the space and aerospace sectors.

“It is so exciting to continue our rich history in this area. When I was a first-year ceramic engineering student at Alfred, I was able to participate in the Zero-G Flight Opportunities Program hosted by NASA and it had a huge impact on me,” said Dr. Gabrielle Gaustad ’04, dean of the Inamori School of Engineering and associate provost for research at Alfred University. Gaustad was referring to her time as an Alfred University undergraduate, when she participated in a NASA research fellowship in Houston, TX. “It is full circle to be here now as dean and see all the enthusiasm and skillsets our current students have for the space sector.”

Current efforts at Alfred University with agencies and industry include projects with NASA, ARPA-E, U.S. Department of Energy, U.S. Army Research Laboratories (ARL), SpaceX, Blue Origin, Safran Aerosystems, Lockheed Martin, Washington Mills, Lithoz, and Blue Star Advanced Manufacturing.

Washington Mills and Blue Star Advanced Manufacturing are New York State industry supporters of Alfred University’s Space Materials Institute (SMI). Pictured above, from left, are Dr. Matt Creedon ’84, Ph.D. ’96 (both, ceramic engineering), research and development manager at Washington Mills; Dr. Holly Shulman ’87 (ceramic engineering), president of Blue Star Advanced Manufacturing, SMI director, and research professor in ceramic engineering at Alfred University; Braden Heim, senior ceramic engineering major at Alfred University, who was an intern at Washington Mills; and Tara Linneman ’22 (ceramic engineering), development engineer at Washington Mills.

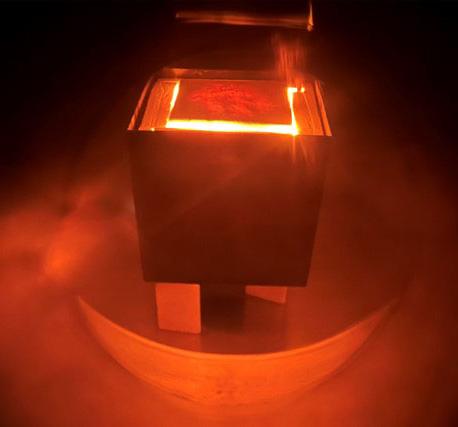

Alfred University senior ceramic engineering major Braden Heim served as an intern at Washington Mills, helping the company develop a Highlands lunar regolith simulant (artificial lunar dust) for NASA. The material is now commercially available for experimentation and testing so that processes can be developed on Earth for eventual “in situ resource utilization” of actual materials found on the moon. Dr. Holly Shulman ’87, president of Blue Star Advanced Manufacturing, working on the NASA Moon to Mars Planetary Autonomous Construction Technologies (MMPACT), is developing microwave solidification of the lunar regolith simulant developed by Washington Mills for use in constructing landing pads and roads, and for 3D building on the moon.

A joint project between Alfred University and DEVCOM (U.S. Army Capabilities Development Command), Army Research Laboratory—funded by a $13.5 million federal contract over five years—studies forming and characterization of ultra-high temperature ceramic (UHTC) materials. Research at Alfred University also focuses on discovering next-generation UHTCs while characterization of a wide range of UHTC materials provides a pathway to making improved materials for defense systems and aerospace applications. These materials must be able to withstand the extreme temperatures that result from traveling at speeds greater than Mach 5. Scott Misture ’90, Ph.D. ’95, Inamori Professor, materials science and engineering, serves as principal investigator.

“Alfred University is excited to bring all of these high-value projects and others together in the Space Materials Institute,” said Mark Zupan, Alfred University president. “We will be able to leverage even more opportunities for growth in this sector for our students, staff, and faculty in addition to our collaborators in industry.”